Cable Laid Endless Steel Core Wire Rope Sling

Cable Laid Endless Steel Core Wire Rope Sling Cable Laid Grommets Manufacturerr As a cable laid grommets manufacturer in

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GLGH |

| Power Source | Hydraulic |

| Shape | Soft Loop |

| Certification | GS, RoHS, ISO 9001 |

| Sling Color | Customized |

| Model No. | Endless |

| Transport Package | Wooden Case or Carton |

| Specification | 6*37(a), 6*61(a), 8*61(a), 8*61(ab) |

| Trademark | Sichwirerope |

| Origin | China |

| HS Code | 7312900000 |

Product Description

Cable Laid Endless Steel Core Wire Rope Sling

| 1.Steel Grade: | Bao steel , Sha steel , 45#,55#, 60# ,65# ,70# ,75# |

| 2.Construction: | 6×37(a), 6×61(a), 8×61(a), 8×61(ab) |

| 3.Diameter Range: | 6 mm- 696 mm |

| 4.Lay: | Right regular lay, Left regular lay, right lang's lay, left lang's lay |

| 5.Coating | Galvanization (with/without lubricant) and smooth surface (with lubricant). |

| 6.Tensile of strength: | 1770MPa |

| 7.Packaging Details: | In plywood reel/plastic reel/wooden reel/coil packing , and then can be palletized or put into a crate. |

| 8. Standard: | EN, GB,ISO,BS,DIN,AS,JIS,ASME,and WSTDA |

| 9.Certification: | BV,DNV,CCS,ABS,CR,GS,CNAS |

| 10. MOQ: | From 100M |

| 11.Delivery Time: | By order |

| 12.Payment Terms: | T/T, Western Union, |

Cable Laid Grommets Manufacturerr

As a cable laid grommets manufacturer in China for over 40 years, we supply cable laid grommets with single leg, 2 leg, and 4 leg with EN13414-3:2003, GB/T30587-2014 standards. You can also contact us for OEM / ODM at any time.

How to bulk cable laid wire rope grommets in our wire rope sling manufacturer?

You can bulk our main types of cable laid wire rope grommet GLGH from our wire rope sling manufacturer.* EXAMPLE: For one high-performance cable laid wire rope grommet (6*37(a), 6*61(a), 8*61(a), 8*61(ab) type), 66mm cable diameter, and 5m sling functional length. YOu CAN ORDER: CLGH66-5.

Cable Laid Wire Rope Grommet Capacity Chart:

Model

| Cable Diameter (mm)

| Minimum Breaking Limit (ton)

| Single-Limb WLL(t) | Double-Limb WLL(t) | Quad-Limb WLL(t) | ||

a= 0° | a≤45° 45°<a ≤60° | a ≤ 45° 45°<a≤60° | |||||

CLGH66 | 66 | 317.1 | 63.4 | 88.8 | 63.4 | 133.2 | 95.1 |

CLGH72 | 72 | 377.4 | 75.5 | 105.7 | 75.5 | 158.5 | 113.2 |

CLGH78 | 78 | 442.9 | 88.6 | 124.0 | 88.6 | 186.0 | 132.9 |

CLGH84 | 84 | 513.7 | 102.7 | 143.8 | 102.7 | 215.7 | 154.1 |

CLGH90 | 90 | 589.7 | 117.9 | 165.1 | 117.9 | 247.7 | 176.9 |

CLGH96 | 96 | 670.9 | 134.2 | 187.9 | 134.2 | 281.8 | 201.3 |

CLGH102 | 102 | 757.4 | 151.5 | 212.1 | 151.5 | 318.1 | 227.2 |

CLGH108 | 108 | 849.1 | 169.8 | 237.7 | 169.8 | 356.6 | 254.7 |

CLGH120 | 120 | 1,048.3 | 209.7 | 293.5 | 209.7 | 440.3 | 314.5 |

CLGH132 | 132 | 1,268.4 | 253.7 | 355.2 | 253.7 | 532.7 | 380.5 |

CLGH144 | 144 | 1,509.5 | 301.9 | 422.7 | 301.9 | 634.0 | 452.9 |

CLGH156 | 156 | 1,771.6 | 354.3 | 496.0 | 354.3 | 744.1 | 531.5 |

CLGH168 | 168 | 2,054.6 | 410.9 | 575.3 | 410.9 | 862.9 | 616.4 |

CLGH180 | 180 | 2,358.6 | 471.7 | 660.4 | 471.7 | 990.6 | 707.6 |

CLGH192 | 192 | 2,683.6 | 536.7 | 751.4 | 536.7 | 1,127.1 | 805.1 |

CLGH204 | 204 | 3,029.5 | 605.9 | 848.3 | 605.9 | 1,272.4 | 908.9 |

CLGH210 | 210 | 3,210.3 | 642.1 | 898.9 | 642.1 | 1,348.3 | 963.1 |

CLGH216 | 216 | 3,301.0 | 660.2 | 924.3 | 660.2 | 1,386.4 | 990.3 |

CLGH228 | 228 | 3,678.0 | 735.6 | 1,029.8 | 735.6 | 1,544.7 | 1103.4 |

CLGH240 | 240 | 4,075.3 | 815.1 | 1,141.1 | 815.1 | 1,711.6 | 1222.6 |

CLGH252 | 252 | 4,493.0 | 898.6 | 1,258.0 | 898.6 | 1,887.1 | 1347.9 |

CLGH264 | 264 | 4,931.1 | 986.2 | 1,380.7 | 986.2 | 2,071.1 | 1479.3 |

CLGH276 | 276 | 5,389.6 | 1,077.9 | 1,509.1 | 1,077.9 | 2,263.6 | 1616.9 |

CLGH288 | 288 | 5,868.4 | 1,173.7 | 1,643.2 | 1,173.7 | 2,464.7 | 1760.5 |

CLGH300 | 300 | 6,367.7 | 1,273.5 | 1,782.9 | 1,273.5 | 2,674.4 | 1910.3 |

CLGH312 | 312 | 6,887.3 | 1,377.5 | 1,928.4 | 1,377.5 | 2,892.7 | 2066.2 |

CLGH324 | 324 | 7,427.2 | 1,485.4 | 2,079.6 | 1,485.4 | 3,119.4 | 2228.2 |

CLGH330 | 330 | 7,482.2 | 1,496.4 | 2,095.0 | 1,496.4 | 3,142.5 | 2244.7 |

CLGH336 | 336 | 7,756.7 | 1,551.3 | 2,171.9 | 1,551.3 | 3,257.8 | 2327.0 |

CLGH348 | 348 | 8,320.7 | 1,664.1 | 2,329.8 | 1,664.1 | 3,494.7 | 2496.2 |

CLGH360 | 360 | 8,904.4 | 1,780.9 | 2,493.2 | 1,780.9 | 3,739.9 | 2671.3 |

CLGH372 | 372 | 9,508.0 | 1,901.6 | 2,662.2 | 1,901.6 | 3,993.3 | 2852.4 |

CLGH384 | 384 | 10,131.3 | 2,026.3 | 2,836.8 | 2,026.3 | 4,255.1 | 3039.4 |

CLGH396 | 396 | 10,774.4 | 2,154.9 | 3,016.8 | 2,154.9 | 4,525.2 | 3232.3 |

CLGH408 | 408 | 11,437.2 | 2,287.4 | 3,202.4 | 2,287.4 | 4,803.6 | 3431.2 |

CLGH420 | 420 | 12,119.9 | 2,424.0 | 3,393.6 | 2,424.0 | 5,090.4 | 3636.0 |

CLGH432 | 432 | 12,822.4 | 2,564.5 | 3,590.3 | 2,564.5 | 5,385.4 | 3846.0 |

CLGH444 | 444 | 13,544.6 | 2,708.9 | 3,792.5 | 2,708.9 | 5,688.7 | 4063.4 |

CLGH456 | 456 | 14,286.7 | 2,857.3 | 4,000.3 | 2,857.3 | 6,000.4 | 4286.0 |

CLGH468 | 468 | 15,048.5 | 3,009.7 | 4,213.6 | 3,009.7 | 6,320.4 | 4514.5 |

CLGH480 | 480 | 15,830.1 | 3,166.0 | 4,432.4 | 3,166.0 | 6,648.6 | 4749.0 |

CLGH492 | 492 | 16,631.5 | 3,326.3 | 4,656.8 | 3,326.3 | 6,985.2 | 4989.4 |

CLGH504 | 504 | 17,452.7 | 3,490.5 | 4,886.8 | 3,490.5 | 7,330.1 | 5235.8 |

CLGH516 | 516 | 18,293.7 | 3,658.7 | 5,122.2 | 3,658.7 | 7,683.3 | 5488.1 |

CLGH528 | 528 | 19,154.4 | 3,830.9 | 5,363.2 | 3,830.9 | 8,044.9 | 5746.3 |

CLGH540 | 540 | 20,035.0 | 4,007.0 | 5,609.8 | 4,007.0 | 8,414.7 | 6010.5 |

CLGH552 | 552 | 20,935.3 | 4,187.1 | 5,861.9 | 4,187.1 | 8,792.8 | 6280.6 |

CLGH564 | 564 | 21,855.4 | 4,371.1 | 6,119.5 | 4,371.1 | 9,179.3 | 6556.6 |

CLGH576 | 576 | 22,795.3 | 4,559.1 | 6,382.7 | 4,559.1 | 9,574.0 | 6838.6 |

CLGH588 | 588 | 23,755.0 | 4,751.0 | 6,651.4 | 4,751.0 | 9,977.1 | 7126.5 |

CLGH600 | 600 | 24,734.5 | 4,946.9 | 6,925.7 | 4,946.9 | 10,388.5 | 7420.4 |

CLGH612 | 612 | 25,733.8 | 5,146.8 | 7,205.5 | 5,146.8 | 10,808.2 | 7720.1 |

CLGH624 | 624 | 26,752.9 | 5,350.6 | 7,490.8 | 5,350.6 | 11,236.2 | 8025.9 |

CLGH636 | 636 | 27,791.7 | 5,558.3 | 7,781.7 | 5,558.3 | 11,672.5 | 8337.5 |

CLGH648 | 648 | 28,850.4 | 5,770.1 | 8,078.1 | 5,770.1 | 12,117.2 | 8655.1 |

CLGH660 | 660 | 29,928.8 | 5,985.8 | 8,380.1 | 5,985.8 | 12,570.1 | 8978.6 |

CLGH672 | 672 | 31,027.0 | 6,205.4 | 8,687.6 | 6,205.4 | 13,031.3 | 9308.1 |

CLGH684 | 684 | 32,145.0 | 6,429.0 | 9,000.6 | 6,429.0 | 13,500.9 | 9643.5 |

CLGH696 | 696 | 33,282.8 | 6,656.6 | 9,319.2 | 6,656.6 | 13,978.8 | 9984.8 |

- Conform Standard: EN13414-3:2003, GB/T30587-2014;

- The high-performance series have a much bigger working load limit compared to grommets for general purpose.

- Wire rope pattern series 6×37(a), 6×61(a), 8×61(a), 8×61(ab) are used in the grommets listed above, their nominal tensile strength is 1770MPa.

- Option for wire rope coating includes galvanization(with/without lubricant) and smooth surface (with lubricant).

- Wire ropes used in each sling can be customized to apply for higher or lower workloads.

- Minimal Breaking workload for the listed wire rope slings is 5 times their working load limit. Cables can be customized to fit various safety coefficient (SC) levels, e.g. grommet diameter≤60mm required SC level 5, grommet diameter between 60mm and 150mm (included) require SC level 6.33-0.0322D, and grommet diameter>150mm require SC level ≥3.

- The perimeter of the grommets is approximately 35 times their diameter.

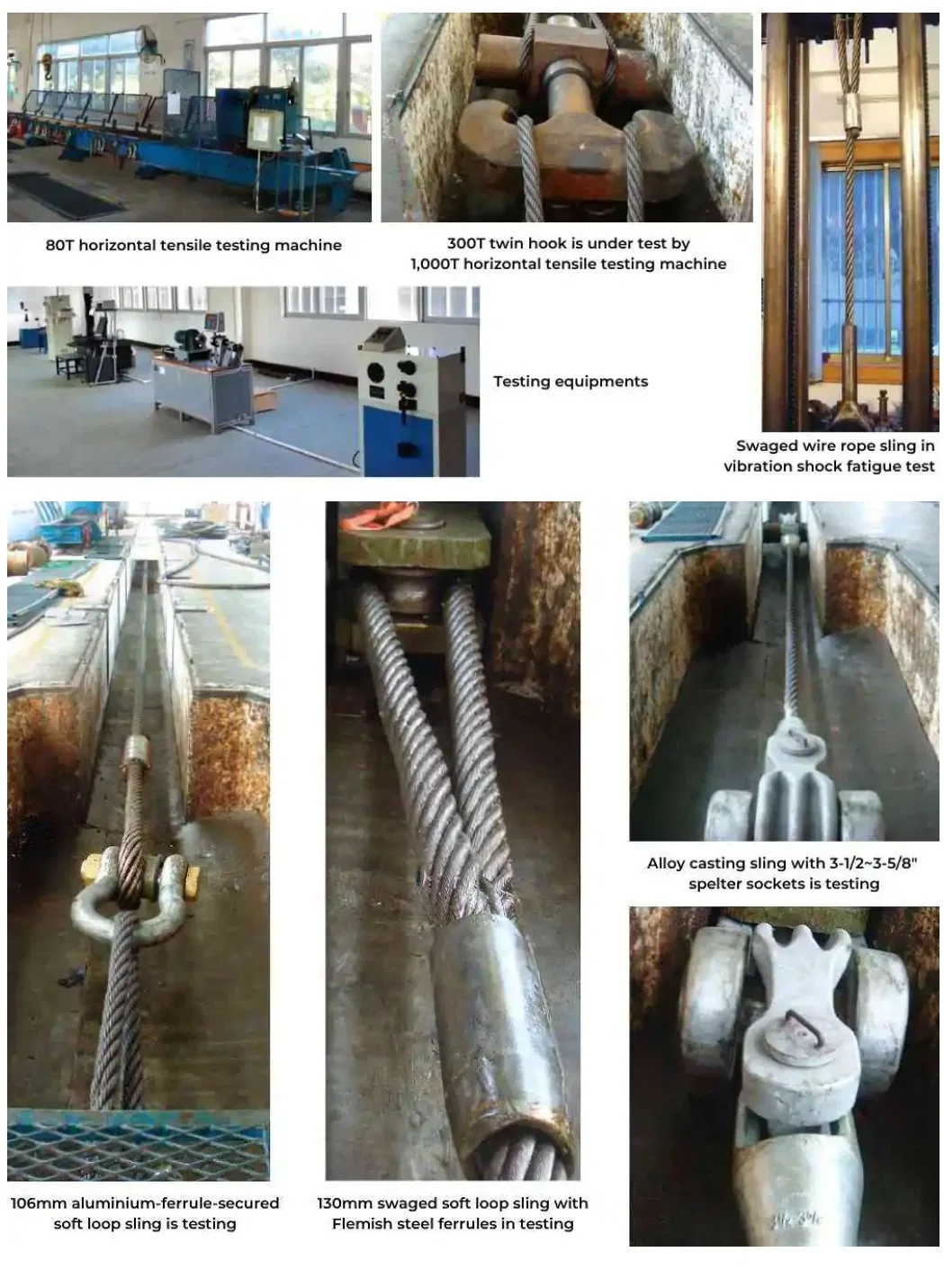

Why Choose the SichWirerope Mechanically Spliced Wire Rope Sling Manufacturer?

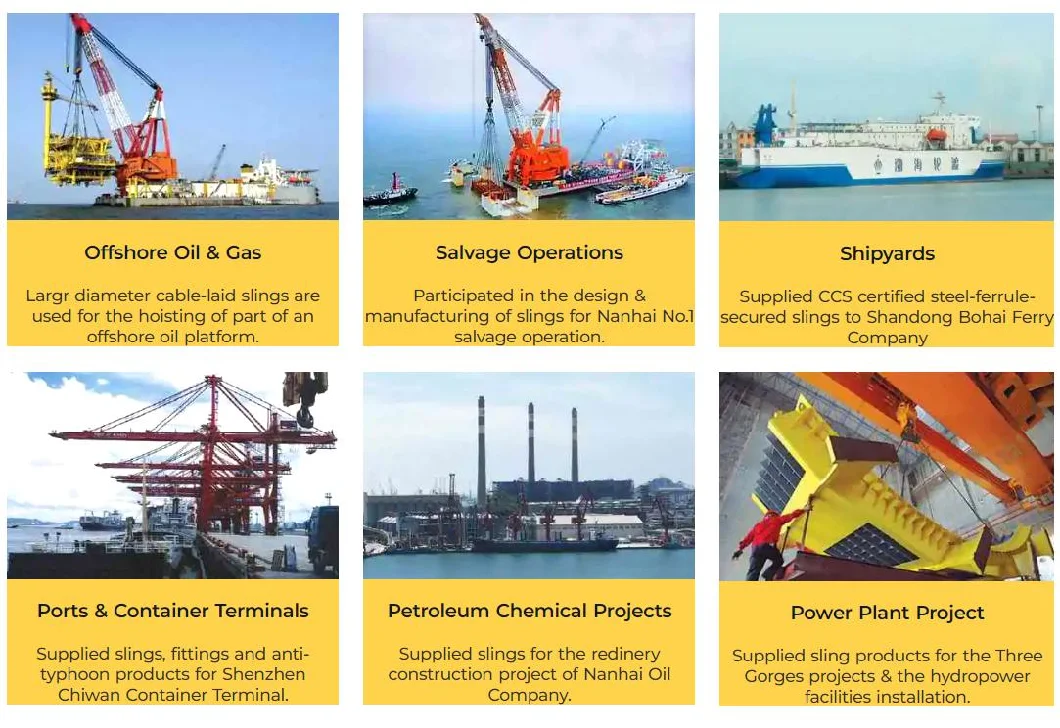

Cases

Global Contract Suppliers

> SichWirerope manufacturer the wire rope slings have been exported to more than 60 countries and districts such as Europe, Australia, South America, Japan, Southeast Asia, and the Middle East in the past 40 years.

> Our brand the JF Brand attends the exhibition every year, such as the USA (Houston) International Petroleum Exhibition (OTC), and Guangzhou International Exhibition in China. So, we have signed contracts with various customers from different countries.

Certification

> The SichWirerope wire rope slings applicable standards: GB, EN, BS, DIN, AS, JIS, ASME, and WSTDA standards.

> We have got a CCS type certificate, DNV type certificate, CE certificate, GS certificate, CNAS national laboratory accreditation

> Supply CCS, DNV, ABS, BV, and other third-party testing services, issue certificates, and have many invention patents.